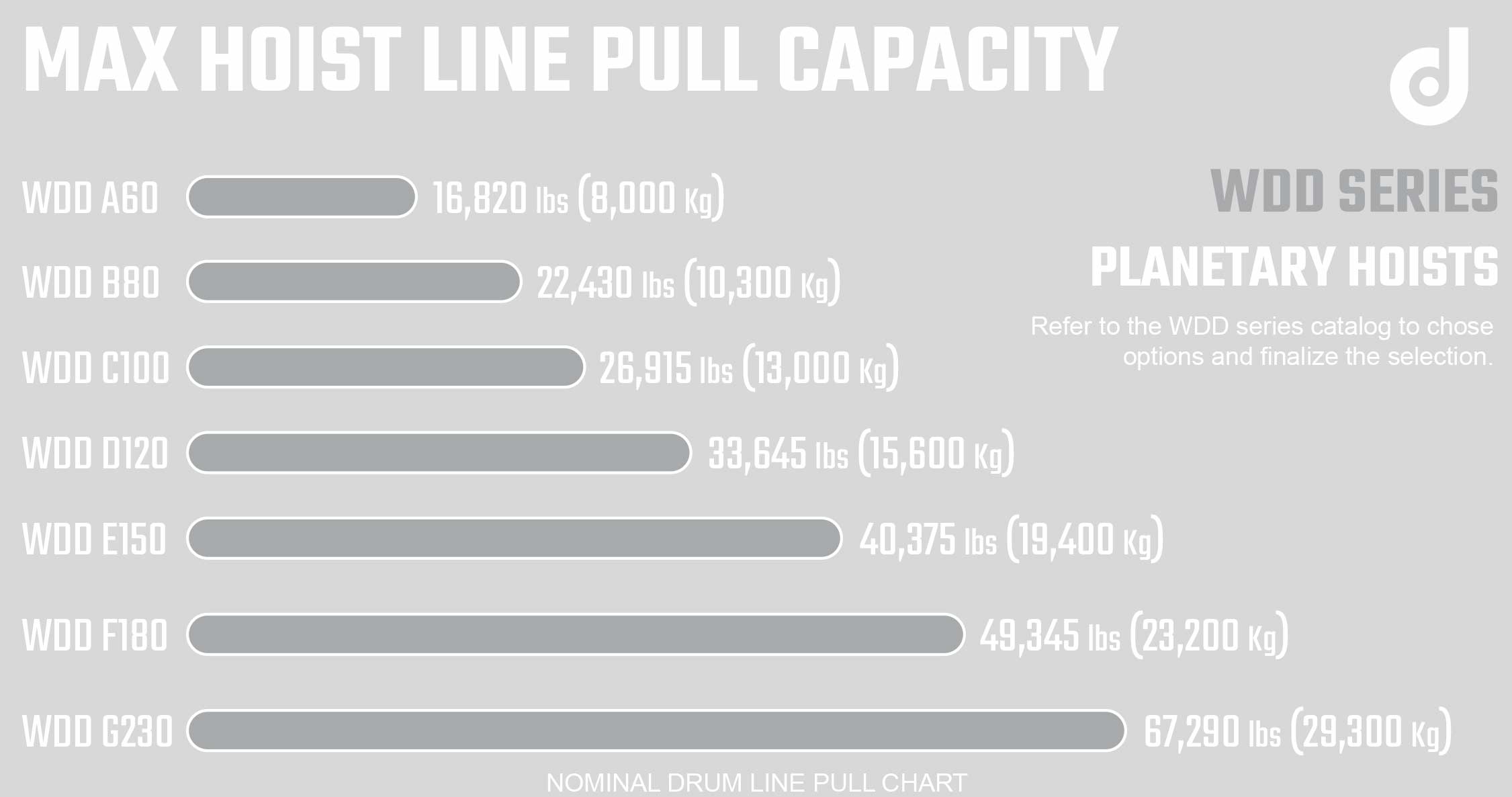

WDD Series Hoists

Dinamic Oil’s Motorized Drums (WDD Series) empower our customers to design their own Hoist. The WDD is composed of a planetary winch drive (WD Series), a cast or fabricated drum and external bearing support. The drum length, flange diameter, drum style (grooved or smooth), reduction ratio, motor input, and brake configuration are all customer-defined. A hydraulic motor and valve can also be provided if required. The WDD Series offers 16,000 to 70,000 lbs (custom configuration) of nominal line pull.

Features

- All hoists are dynamically tested prior to shipment

- Smooth or grooved drums

- Under or over wound, CW and CCW hoisting directions

- Negative static multi-disc brake & sprag clutch

- 98% efficient planetary gears

- Oil level kit can be site, stainless steel or with a dipstick

- API 2C compliant

- Orbit, gear or axial piston motor configurations

- Gear ratio, drum length, and flange height can be customized

- Based on our WD winch drive technology

Dynamic Hoist Testing

In order to provide a superior hoist experience, we dynamically test every Hoist prior to shipment. Testing ensures your Hoist will work as designed, every time. The test process consists of hoist installation on our multi-configuration test bench, cable spooling, load selection, and test cycle.

Benefits of dynamic testing include:

- Every Hoist assembled or repaired is subject to dynamic testing

- Ensures product is ready for use when you are

- Used for custom and prototype testing

- Ensures counterbalance valves are configured properly

- Line Pull verification by pressure (PSI)

- Line Speed verification by flow (GPM)

- Recertification of API 2C Hoists

- Test certificates available by serial number upon request

The system can provide 50 GPM and 4500 psi, and the computerized control center allows us to set a relief pressure or flow rate and is pre-configured for prototype or production hoists.

Test procedure includes:

- Static and dynamic seal test

- Brake hold test

- Sprag clutch test

- Ascent and descent under 50% load

- Verification of line pull and speed at given PSI and GPM

- Log test results by serial number

Literature

Hoist Catalog

Maintenance Manual

We are a global company and provide our maintenance manuals in multiple languages. Please scroll through the document until you find the appropriate section.

Specifications

Accessories

Every application is unique and has different requirements. Our hoists can accommodate a variety of accessories to ensure maximum efficiency, safety, and productivity.

Auxiliary Drum & Band Brakes

In mission-critical hoist applications (personnel handling), auxiliary brakes may be required to operate directly on the drum. All of our auxiliary brakes are designed to stop in excess of the full drum torque, and function in a negative static fail-safe condition. We offer pneumatic or hydraulic operated drum band brakes, external caliper disc brakes on the drum flange, or auxiliary brakes off the anti-rotation flange.

Benefits include:

- Fail-safe design for personnel handling hoists

- Large selection of brake types and torques

- Optional accessory for SRD, WDD series hoists

Cable Tensioners

Cable Tensioners are optional accessories that assist with cable spooling and can help to extend the life of your cable. The tensioner is composed of rust protected steel and nitrile rubber rollers running on high-efficiency spherical bearings. This accessory is proving to be increasingly popular with customers who look to improve cable spooling under no-load conditions.

Cable Tensioner features:

- Rust Protected Steel and nitrile rubber ensure a long lifetime

- Available on all A, SRD, NP, P, S and SE series Hoists

- Improves spooling

- Easy to install

Last Wrap Indicators

Last Wrap Indicators are an extremely valuable precautionary safety accessory. When spooling out cable, it is critical to ensure that at least three wraps of cable remain on the drum at all times. This accessory is integral to our proprietary Cable Tensioner and consists of a dual diameter tensioner bar, mechanical lever arm, and Pizzato GO/NO-GO sensor. The sensor ensures that personnel and load safety is guaranteed by offering a fail-safe signal used to cut power to the motor when the last three wraps are reached.

The dual-diameter Cable Tensioner bar can be modified to provide a 4th or 5th Wrap Indicator, consistent with certain Personnel Handling Certification requirements.

Last Wrap Indicator features:

- Additional security feature

- Can be installed in the field

- Available on all A, NP, P, S, and SRD series of Hoists

Refer back to this page as we regularly add more accessories to complement our product range.