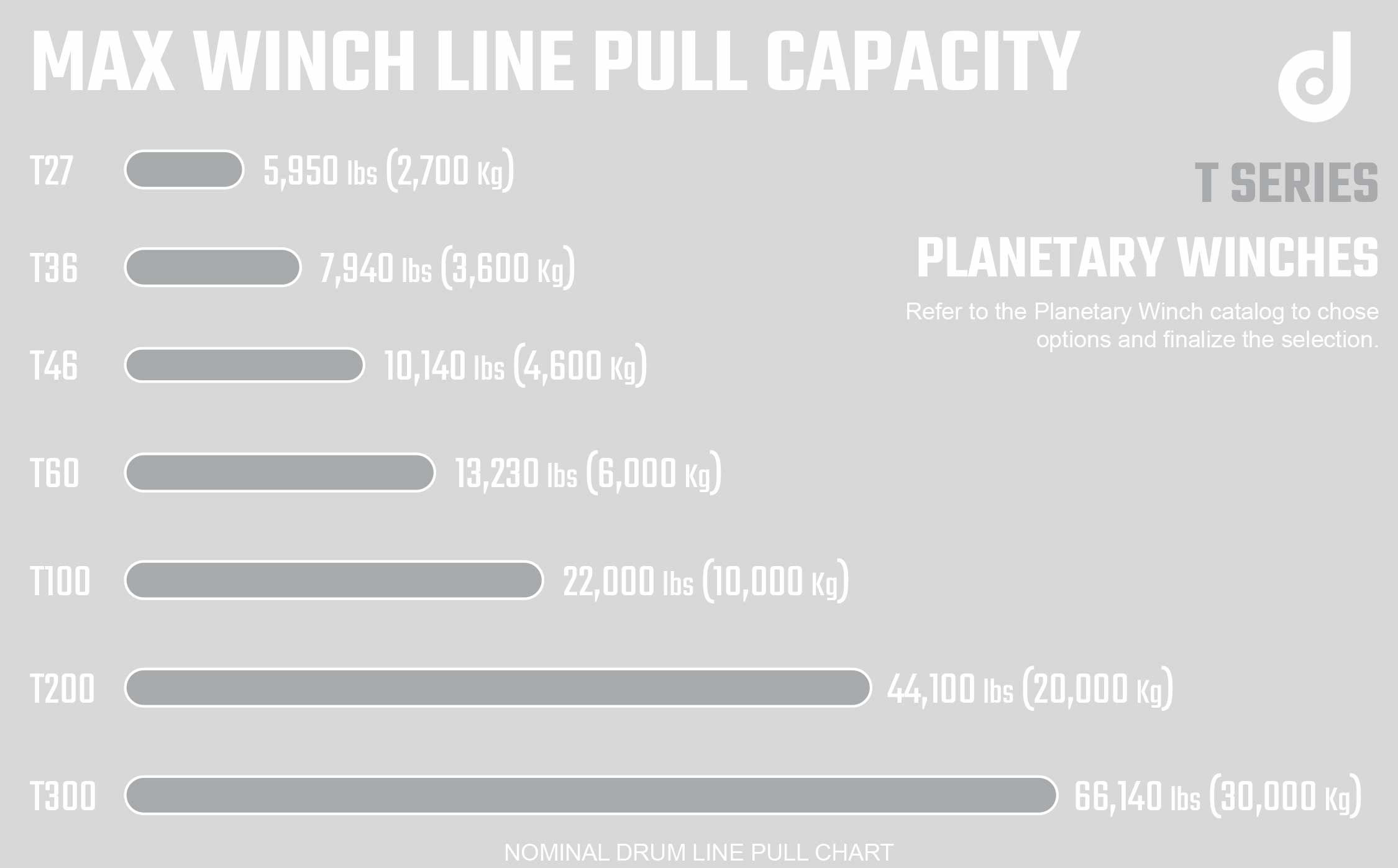

T Series

Dinamic Oil’s recovery winches are designed with the customer in mind to ensure ease of use from installation, use, and maintenance. The series features independent high-efficiency planetary gears, a cast iron drum, and structural steel supports. The recovery winches come complete with a mechanical drum release mechanism, negative static multi-disc brake, hydraulic motor, and control valve.

Features

- Support structure can be adapted to meet various installation requirements

- Standard cast iron smooth drums

- Hydraulic over-center valve prevents the motor from losing control of the load

- Optional cable fairleads and cable tensioners

- Under or overwound, CW and CCW directions

- Drum free spool feature allows the drum to rotate independently, allowing manual cable release

- Optional hydraulic or pneumatic drum free spool feature

- Hydraulic orbit motor and control valve included

- Negative static multi-disc brake

- 98% efficient planetary gears

- Smooth and quiet transmission due to gear design profile

- Low profile design for compact installation saves weight and space

Dynamic Hoist Testing

To ensure all of the winches are field installation-ready, we dynamically test every winch prior to shipment. Testing confirms your winch will work as designed, every time. The test process consists of winch installation on our multi-configuration test bench, cable spooling, load selection, and test cycle.

Benefits of dynamic testing include:

- Every winch assembled or repaired is subject to dynamic testing

- Ensures product is ready for use as soon as you install it

- Used for custom and prototype testing

- Ensures counterbalance valves are configured properly

- Line Pull verification by pressure (PSI)

- Line Speed verification by flow (GPM)

- Test certificates available by serial number upon request

The system can provide 50 GPM and 4500 psi, and the computerized control center allows us to set a relief pressure or flow rate and is pre-configured for prototype or production hoists.

Test procedure includes:

- Static and dynamic seal test

- Brake hold test

- Sprag clutch test

- Ascent and descent under 50% load

- Verification of line pull and speed at given PSI and GPM

- Log test results by serial number

Literature

Winch Catalog

Maintenance Manual

We are a global company and provide our maintenance manuals in multiple languages. Please scroll through the document until you find the appropriate section.

Specifications

Accessories

Every application is unique and has different requirements. Our hoists can accommodate a variety of accessories to ensure maximum efficiency, safety, and productivity.

Cable Tensioners

Cable Tensioners are optional accessories that assist with cable spooling and can help to extend the life of your cable. The tensioner is composed of rust protected steel and nitrile rubber rollers running on high-efficiency spherical bearings. This accessory is proving to be increasingly popular with customers who look to improve cable spooling under no-load conditions.

Cable Tensioner features:

- Rust Protected Steel and nitrile rubber ensure a long lifetime

- Improves spooling

- Easy to install

Cable Fairleads

Cable Fairleads are optional accessories that guide the cable and stop it from moving laterally. The fairleads are welded metal structural components with horizontal and vertical steel rolls mounted on self-lubricating bushings.

Hydraulic or Pneumatic Drum Free Spool

This mechanism makes drum rotation independent and can be controlled hydraulicly or pneumatically. Free spooling allows the wire rope to be pulled off the cable drum by hand.

Wire Rope and Wire Rope Installation

Dinamic Oil can provide the appropriate wire rope and also install it on the winch as a value-added option.

Refer back to this page as we regularly add more accessories to complement our product range.